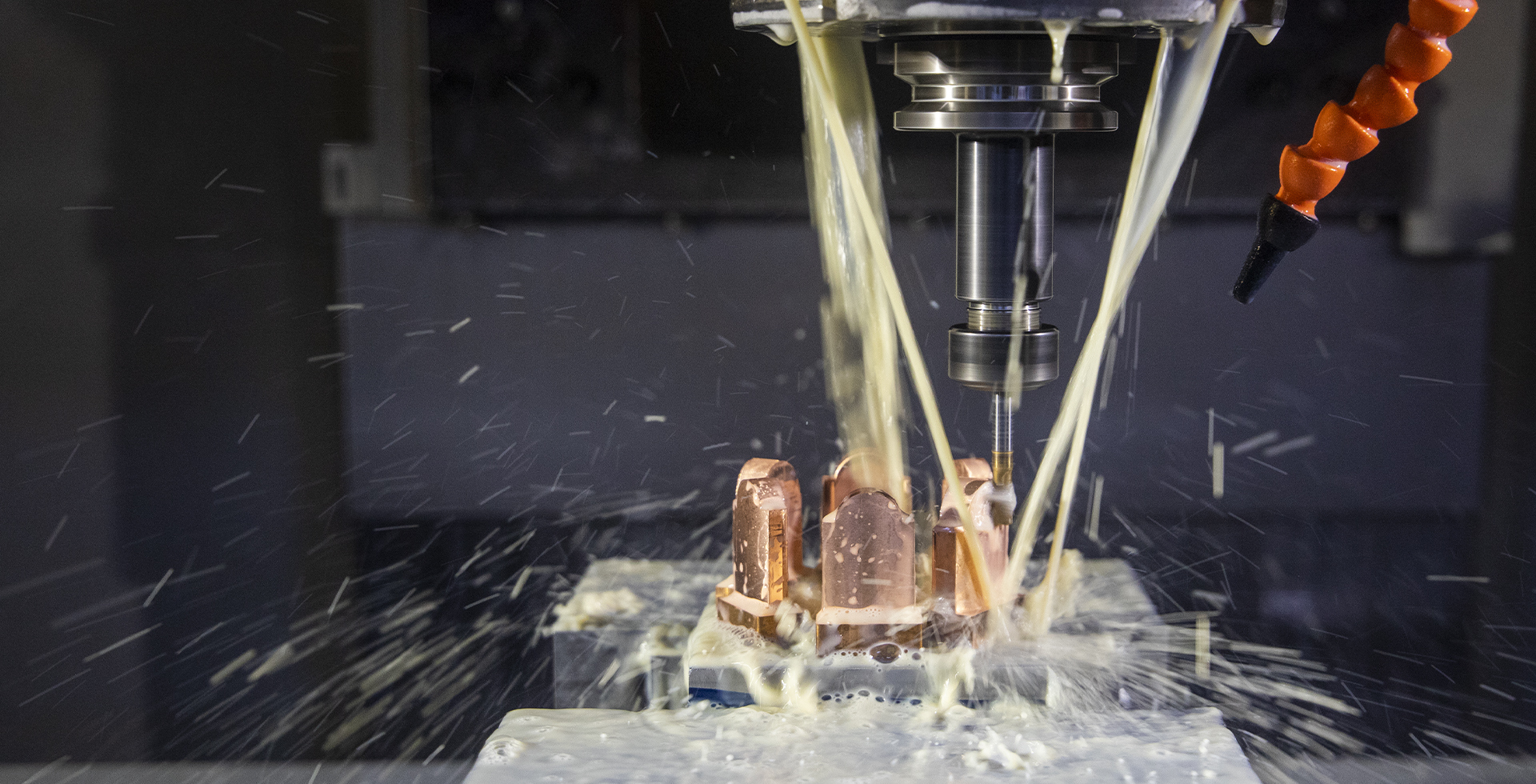

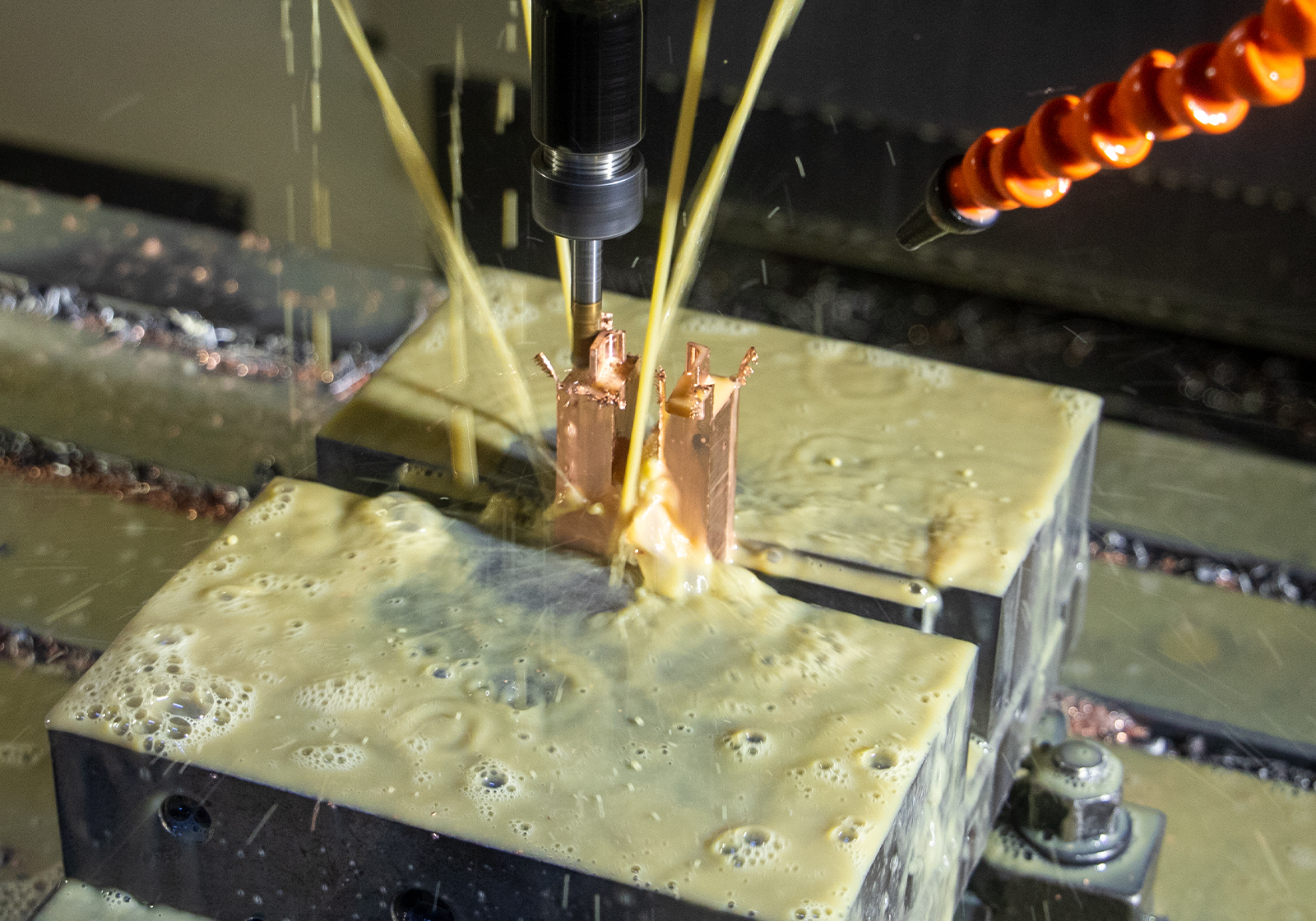

Our company is able to respond to the needs of its customers at every stage by producing high quality long -lasting moulds with the least error with professional programs such as solidworks, mastercam cad / cam in all stages of design manufacturing, testing and evaluation.

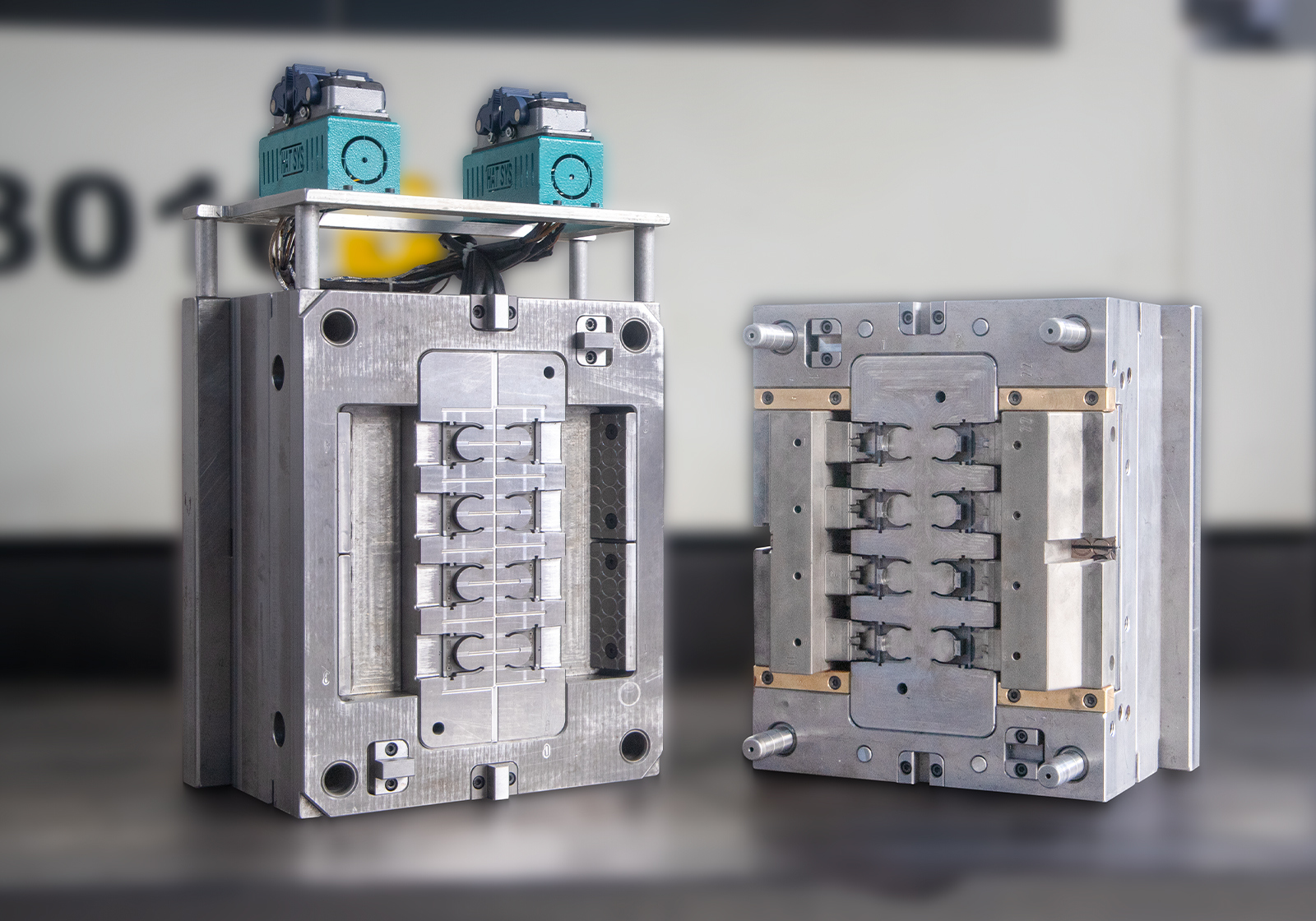

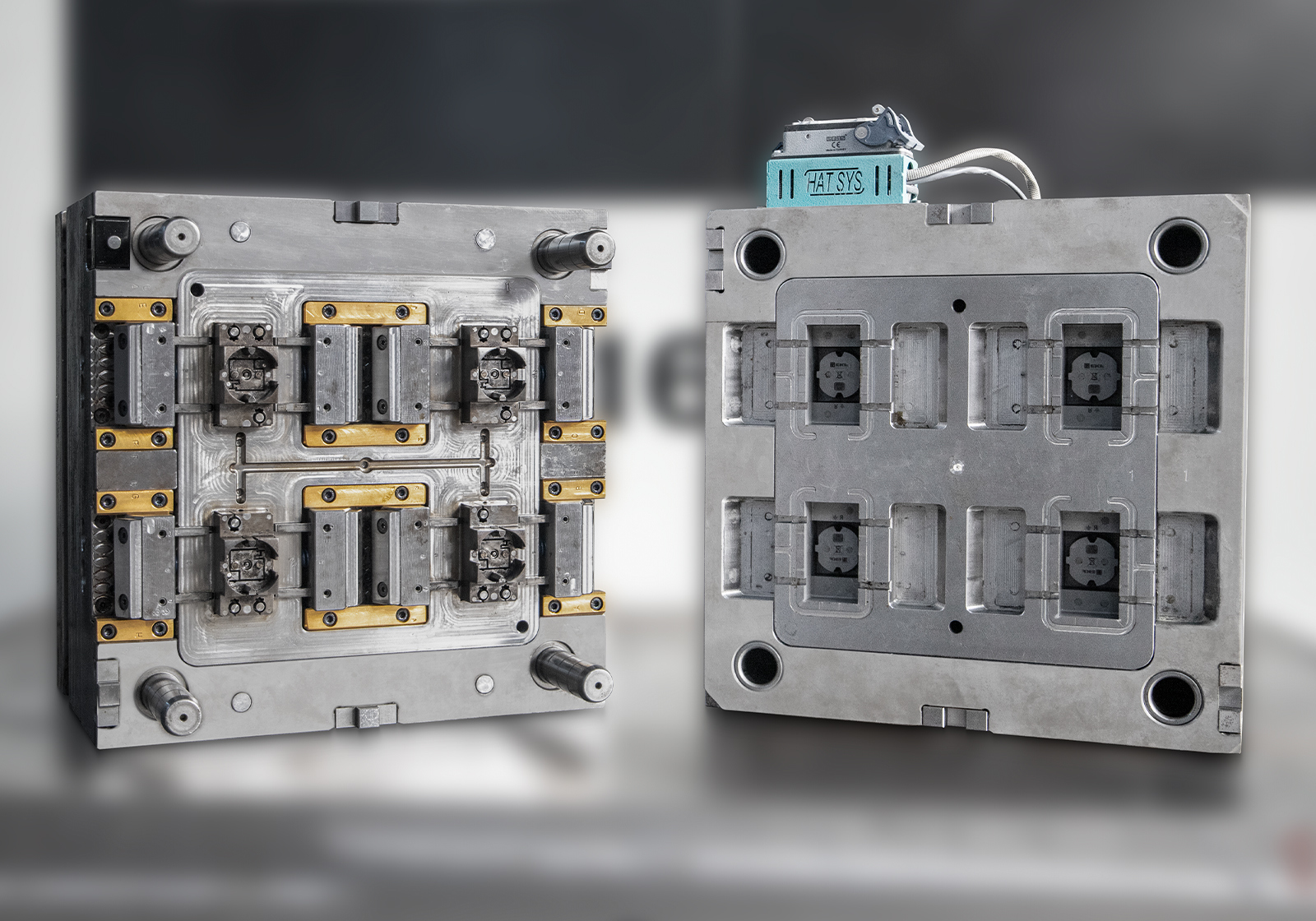

we have taken our place among the leading companies in the sector with high technology,expert staff,short production times and effective AR- GE studies in the field of plastic injection mould production and mannufacturing.

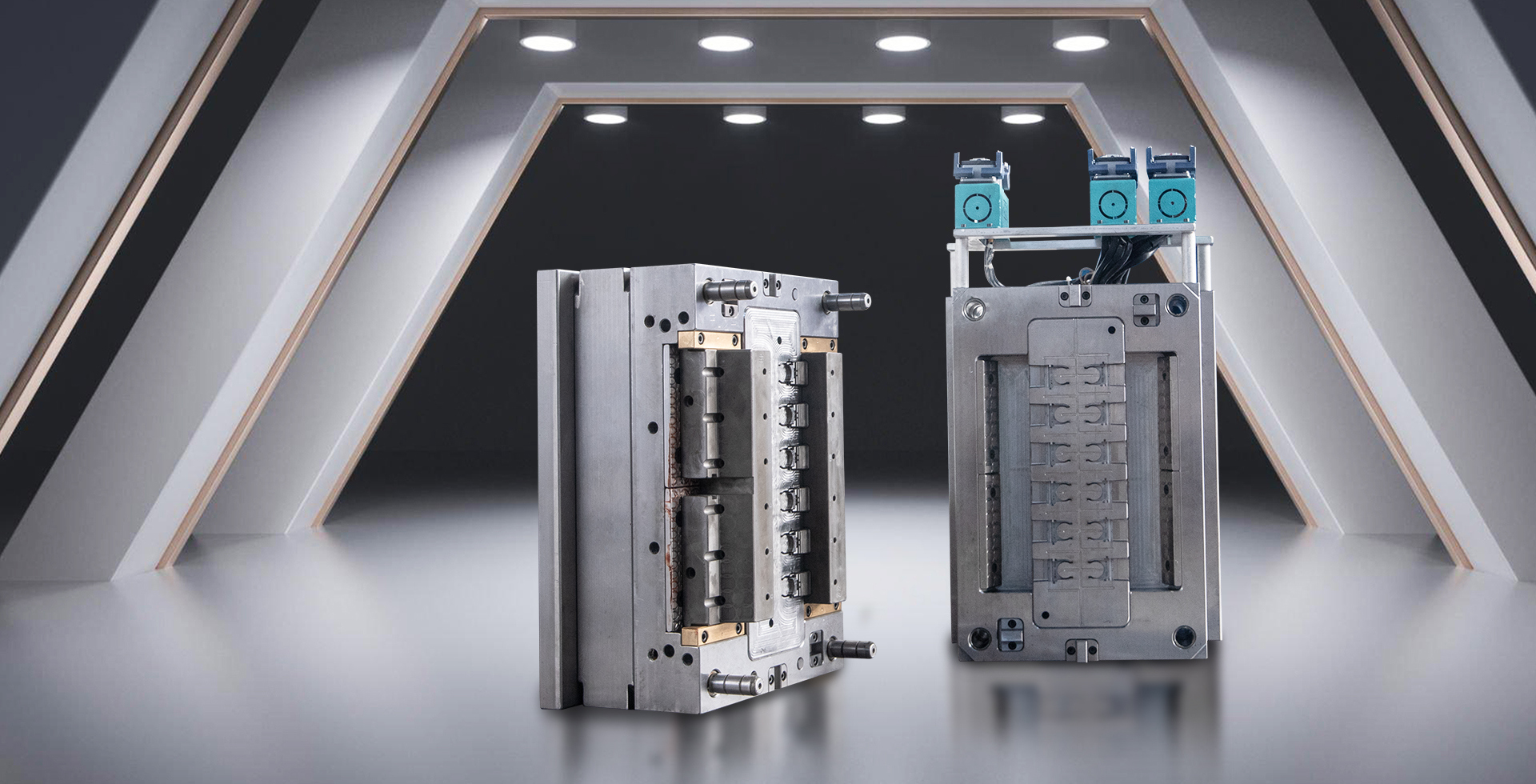

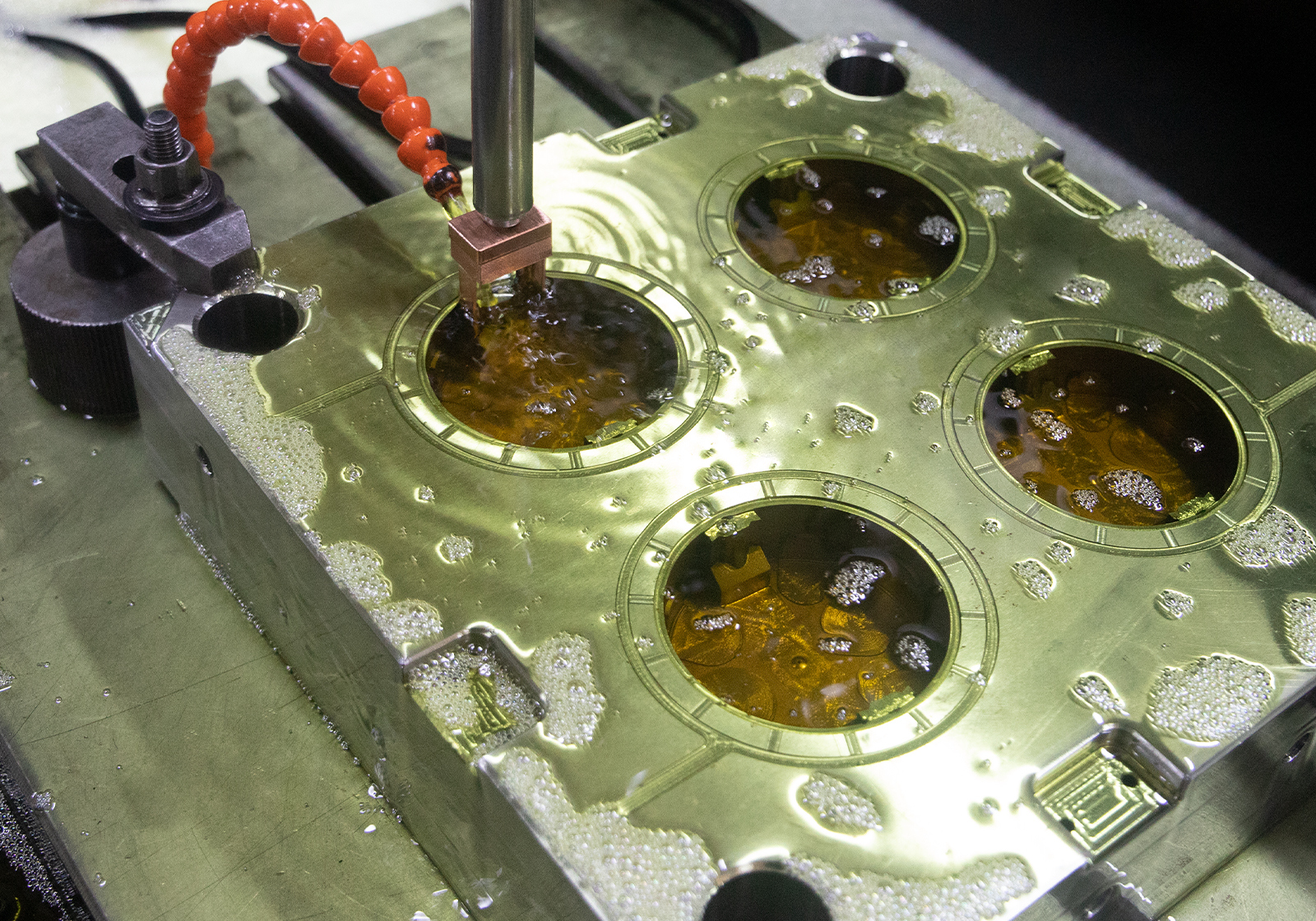

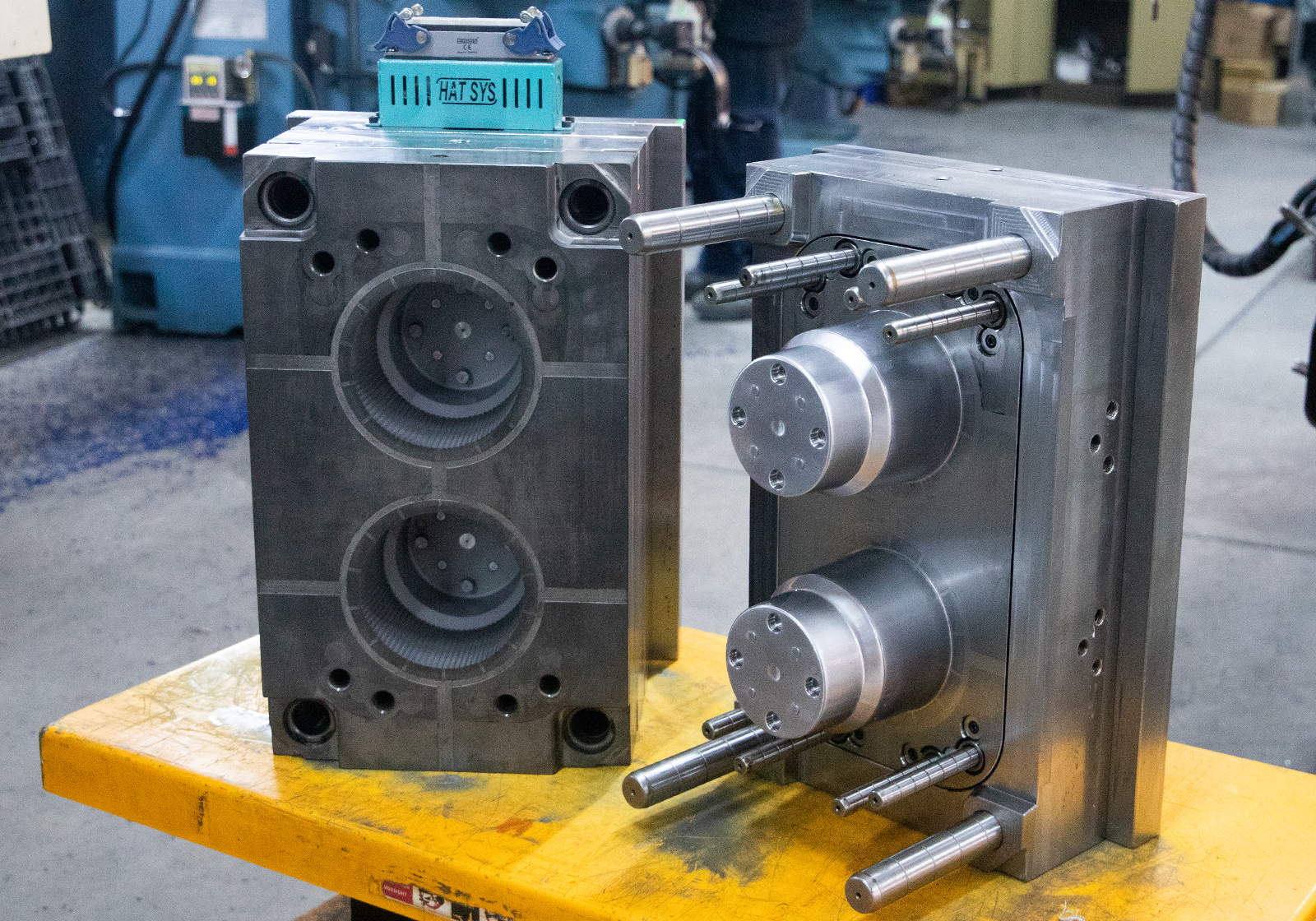

The mould parts produced at each stage of production are sent to the quality control unit for critical measurements and verification.the complete parts are meticulously assembled by our assembly.

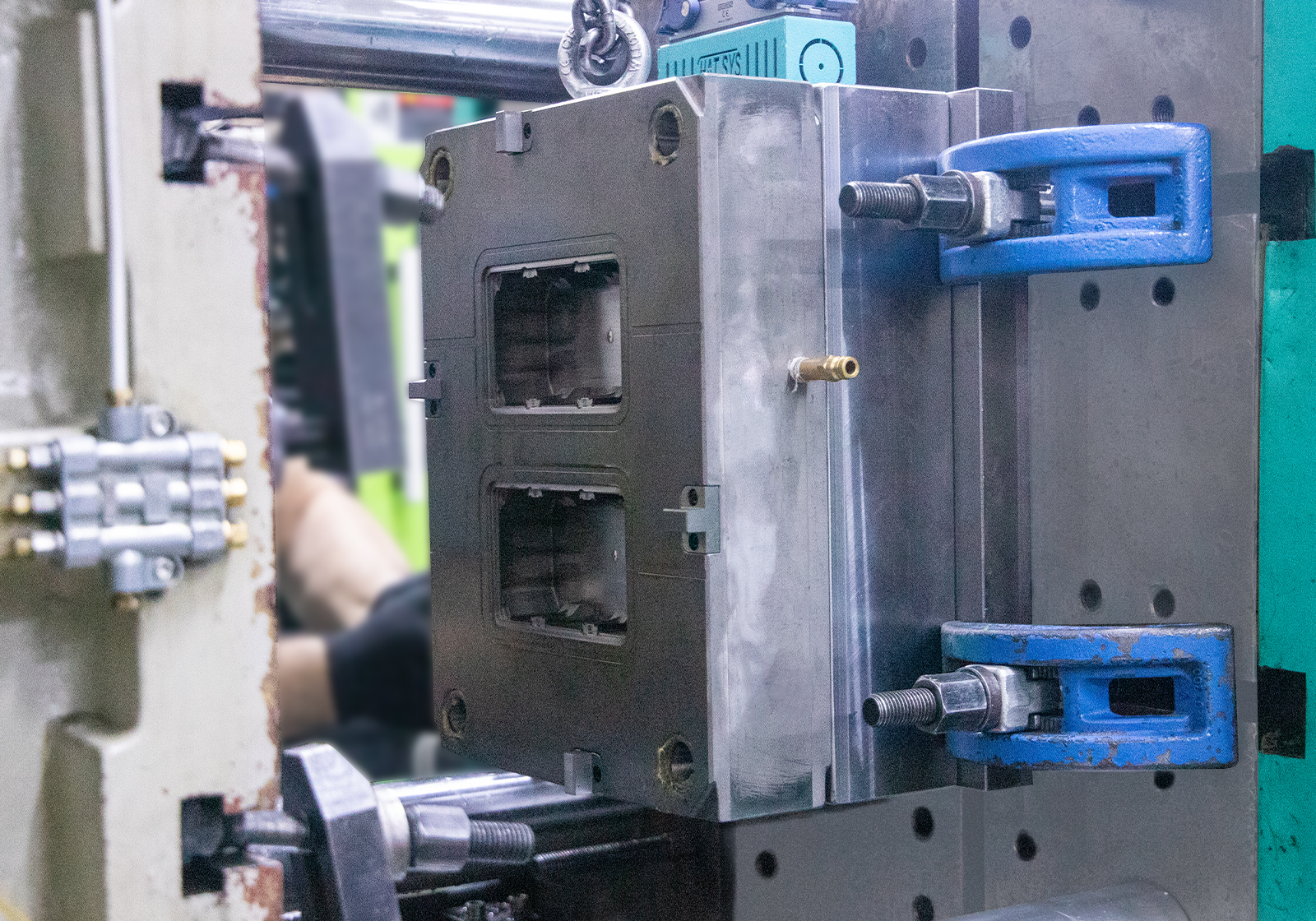

Gorplast, which carries out the trail processes of the plastic injection moulds it has made with its own injection machines, offers its business partners a number of 1.000.0000 prints or a warranty period of up to1 year for the moulds its produces.